粉体行业在线展览

粉体行业在线展览

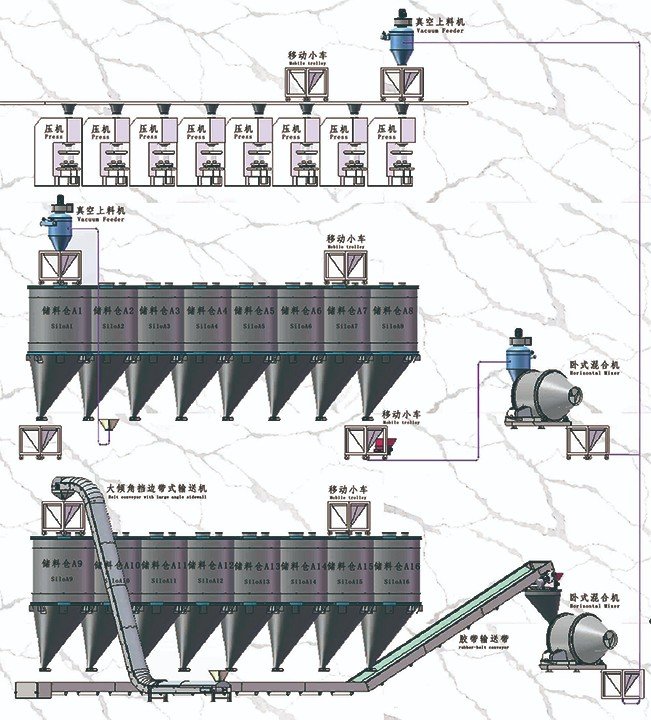

压机无尘自动上料均化系统

面议

新联和

压机无尘自动上料均化系统

2850

无尘车间、压机全自动输送、高效节能、物料改性、物料均化

压机无尘上料系统

系统概述:

1、全流程采用密闭运输,实现无尘化车间,提高物料的洁净度。

2、实现多种物料高精度配料,提高车间生产效率和成品率。

3、根据流程需求系统全自动上料,可实现无人值守,减少人力成本投入。

4、减少设备投入,系统可实现将物料自动送至多台压机。

5、高效节能环保,在大批次送料过程中降低能源消耗。

6、全报表汇总,流程可监控,实现车间数据可视化。

7、适用于新能源、特种陶瓷、医药、冶金、化工、塑料等行业的自动定量配料控制。

Automatic loading system for presses

System Overview:

1.The whole process adopts closed transport, realises dust-free workshop, improves the

cleanliness of materials.

2.realises high-precision dosage of many kinds of materials,improves the production,efficiency of workshop and the rate of finished products.

3.according to the demand of the process the system is fully automatic loading,

can realise unattended, reduces the input of manpower cost, reduces the investment

of equipments, the system can realise the material will be automatically sent to more

than one press.

4.the whole report is summed up, the process can be monitored, realises the data ofthe workshop can be visualized.

5.applies to the new energy, the special ceramics, the medicine, the metallurgy, the

chemical, the plastics and so on the industries of the automatic rationing and dosage control.