粉体行业在线展览

粉体行业在线展览

PLG

面议

佳发

PLG

7799

盘式连续干燥机

应用:无机工产品,医药、食品,饲料、肥料

概述:盘式连续干燥器是一种高效的 传导型连续干燥设备。其独特的结构和工作原理决定了它具有热效率高、能耗低、占地面积小、配置简单、操作控制方便、操作环境好等特点。广泛适用于化工、医药、农药、食品、饲料、农副产品加工等行业的干燥作业。在各行业使用实践中深受好评。先生产制造常压、密闭、真空三大类型,1200、1500、2200、3000四种规格,A(碳钢)、B(接触物了部分均匀不锈钢)、C(在B的基础上,增加蒸汽管路,主轴及支架为不锈钢,筒体和顶盖内衬不锈钢)。三种材质,干燥面积4-180m 2 ,共几百种型号的系列产品,并提供与之相配套的辅助设备,可满足用户对各种物料进行干燥的需求。

原理:

★湿物料自加料器连续地加到干燥器上部**层干燥盘上,带有耙叶的耙臂做回转运动使耙叶连续地翻抄物料。物料沿指数螺旋线流过干燥盘表

面,在小干燥盘上的物料被移送到外缘,并在外缘落到下方的大干燥盘外缘,在大干燥盘上物料向里移动并从中间落料口落入下一层小干燥盘

中。大小干燥盘上下交替排列,物料得以连续地流过整个干燥器。中间的干燥盘内通入加热介质,加热介质形式有饱和蒸汽、热水和导热油,加

热介质由干燥盘的一端进入,从另一端导出。已干物料从*后一层干燥盘落到壳体的底层,*后被耙叶移送到出料口排出。湿份从物料中溢出,

由设在顶盖上的排湿口排出,真空型盘式干燥器的湿气由设在顶盖上的真空泵口抽出。从底层排出的干物料可直接包装。通过配备翅片加热器、

溶剂回收冷凝器、布袋除尘器、干料返混机构、引风机等辅机,可提高其干燥的生产能力,干燥膏糊状和热敏性物料,可方便地回收溶剂,并能

进行热解和反应操作。

特点:

调控容易、适用性强

1、通过调整料层厚度、主轴转速、耙臂数量、耙叶形

式和尺寸可使干燥过程达到**。

2、每层干燥盘皆可单独通入热介质或冷介质,对物料

进行加热或冷却,物料温度控制准确、容易。

3、物料的停留时间可以精确调整。

4、物料流向单一,无返混现象,干燥均匀、质量稳

定、不再需要混合。

Easy control,wide application

1、Regulate thickness of materials ,rotating speed of main shaft, number of

rakearm,style and sizes of harrows achieve best drying process.

2、Each layer of drying plate can be fed with hot or cold media individually to heat or

cold materials and make temperature control accurate and easy.

3、Stay time of materials can be accurately adjusted.

4、Single flowing direction of materials without return flowing and mixing,uniform

drying and stable quality, no re-mixing is required.

操作简单、容易

1、干燥器的开车、停车操作非常简单。

2、停止进料后,传送物料后的耙叶能很快地排空干燥

器内的物料。

3、通过特殊的大规格检视门的视镜,可以对设备内进

行很仔细的清洗和观察。

Easy and simple operation

1、Start and stop of drier is quite simple

2、After material feeding is stopped,they can be easily discharged out of the drier by

harrows.

3、Careful cleaning and observation can be carried inside the equipment throughlarge-

scale viewing window.

能耗低

1、料层很薄,主轴转速低,物料传送系统需要的功率

小,电耗少。

2、以传导热进行干燥,热效率高,能量消耗低。

Low energy consumption

1、Thin layer of materials, low speed of main shaft, small power and energy required

for conveying system of materials.

2、Dry by conducting heat so it has high heating efficiency and low energy

consumption.

操作环境好,可回收溶剂,粉尘排放符合要求

1、常压型:由于设备内气流速度低,而且设备内湿度

分布上高下低,粉尘很难浮到设备顶部,所以顶部排湿

口排出的尾气中几乎不含有粉尘。

2、密闭型:配溶剂回收装置,可方便地回收载湿气体

中的有机溶剂。溶剂回收装置简单,回收率高,对于易

燃、易爆、有毒和易氧化的物料,可用氮气作为载湿气

体进行闭路循环,使之安全操作。特别适用于易燃、易

爆、有毒物料的干燥。

3、真空型:在真空状态下操作的盘式干燥器,特别适

用于热敏性物料的干燥。

Good operation environment,solvent can be recovered and powder discharge meet the

requirements of exhaust.

1、Normal pressure type : as low speed of air flow inside the equipment and moisture

being high in upper part and low in lower part, dust powder could not float to the

equipment, so there is almost no dust powder in tail gas discharged from the moist

discharge outlet on the top.

2、Closed type: equipped with solvent recovery device that can recover organic solvent

easily form moist-carrier gas. The solvent recovery device has simple structure and

high recovery rate, and nitrogen can be used as moist-carrier gas in closed circulation

in order for safe operation . Especially suitable for drying of flammable , explosive and

poisonous materials.

3、Vacuum type: if the plate drier is operating under vacuum state, it is particularly

suitable for drying heat sensitive materials.

安装方便、占地面积小

1、干燥器整体出厂,整体运输,只需吊装就位,安装

定位非常容易。

由于干燥盘层式布置、立式安装,即使干燥面积很大,

占地面积也很小。

Easy installation and small occupying area

1、As the drier is in a whole for die delivery, it is quite easy to install and fix at site only

by hoisting.

As drying plates being arranged by layers and installed vertically, it takes a small

occupying area though drying area is large.

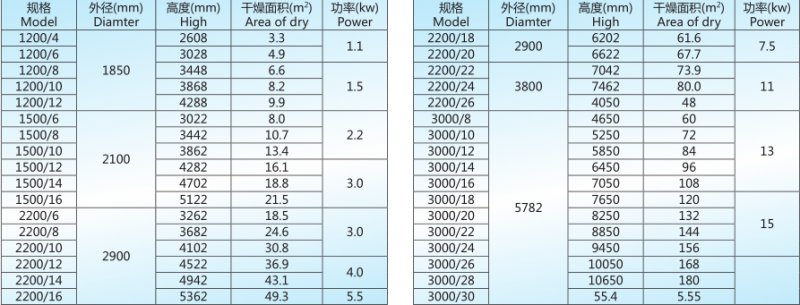

技术参数: